Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

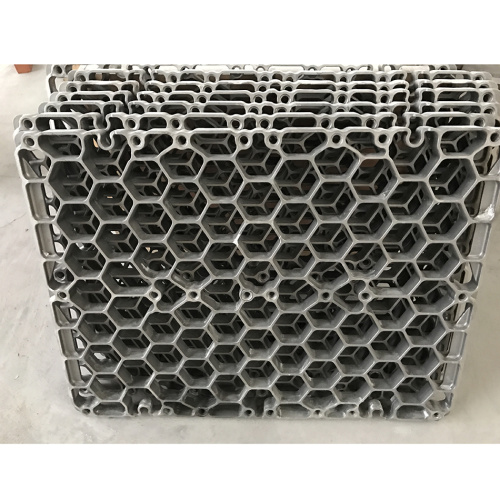

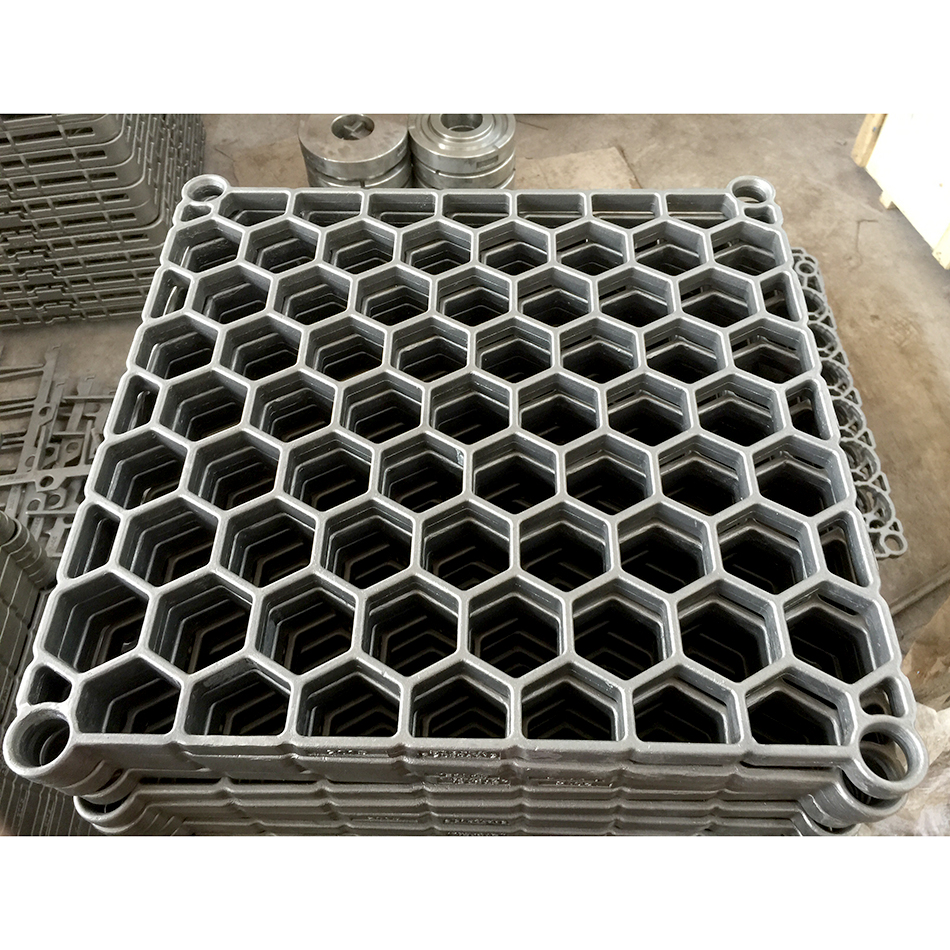

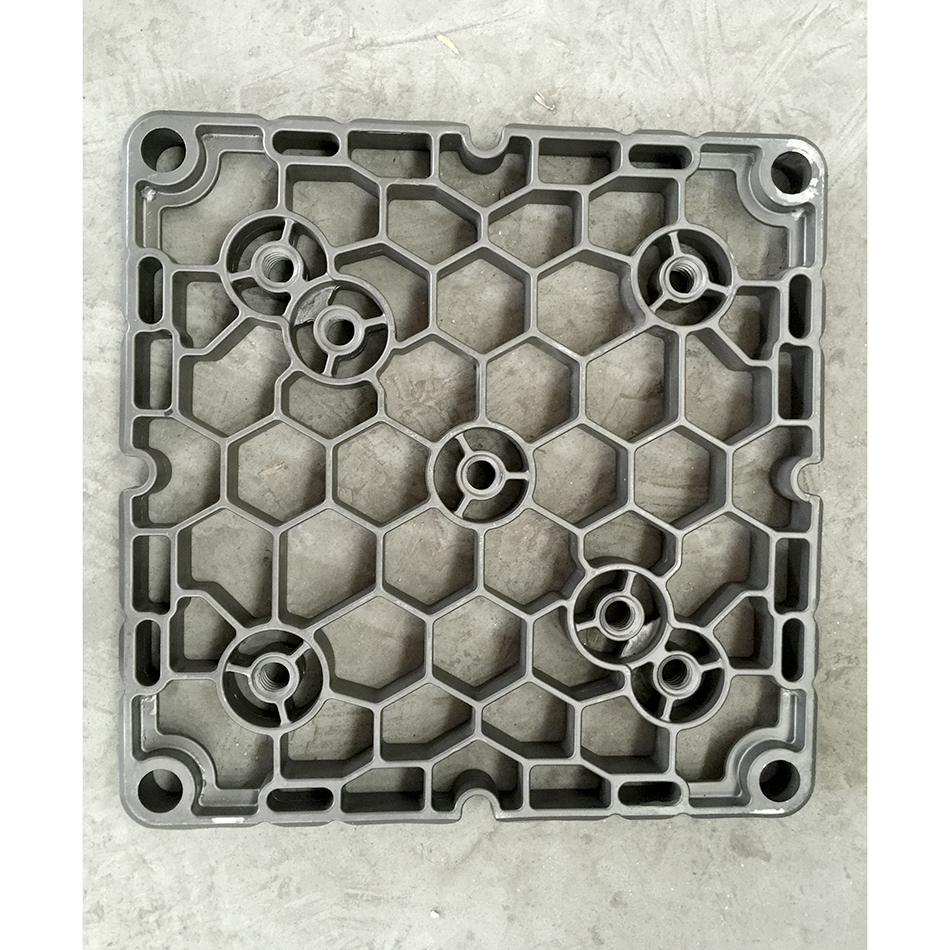

Heat-treated heat-resistant steel casting Furnace Bottom Tray is a heat-resistant steel material that has undergone a special heat treatment process and is used to manufacture chassis components. Heat treatment is a process that changes the internal structure and properties of the material by controlling the heating and cooling process of the material. For heat-resistant steel materials, heat treatment can improve its high temperature resistance and mechanical properties.

Heat treatment heat-resistant steel Heat Treatment Pallet Basket usually uses high-temperature alloy steel materials, such as alloy steel containing elements such as chromium, nickel, and molybdenum. These materials have good high temperature resistance and oxidation resistance and are suitable for chassis components working in high temperature environments.

The manufacturing process of heat-treated heat-resistant steel cast chassis includes the following steps:

1. Material selection: Choose heat-resistant steel materials suitable for high-temperature environments.

2. Casting: Casting technology is used to cast steel into the shape of chassis components.

3. Heat treatment: Heat treatment is the heat treatment of chassis components, which usually includes heating, insulation, cooling and other steps. During the heat treatment process, by controlling temperature and time, the grain structure and phase composition of the material are changed, and its high temperature resistance and mechanical properties are improved.

4. Surface treatment: Surface treatment of Vacuum Furnace Tray parts, such as spraying high-temperature resistant coating, etc., to improve their oxidation resistance and corrosion resistance.

5. Inspection and quality control: Conduct various inspections and quality control on the heat-treated heat-resistant steel casting chassis to ensure that it meets the design requirements and usage requirements.

The heat-treated heat-resistant steel cast chassis has excellent properties such as high temperature resistance, oxidation resistance, and corrosion resistance, and is widely used in high-temperature equipment and machinery in aerospace, petrochemical, electric power and other fields.

Transportation: Ocean,Air

Place of Origin: CHINA

Port: SHANGHAI,ZHENGZHOU,XIAN

Payment Type: T/T

Incoterm: FOB,FCA,CFR,CIF

You Might Also Like

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.